Deactivated yeast, expertly crafted by Lesaffre, serves as a key ingredient for resolving various functional challenges encountered in different types of dough products.

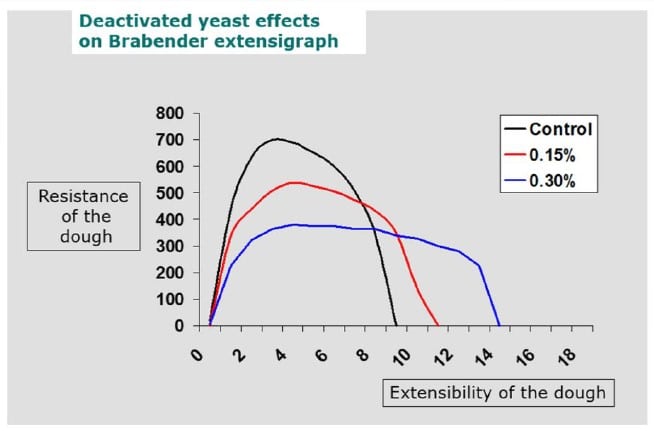

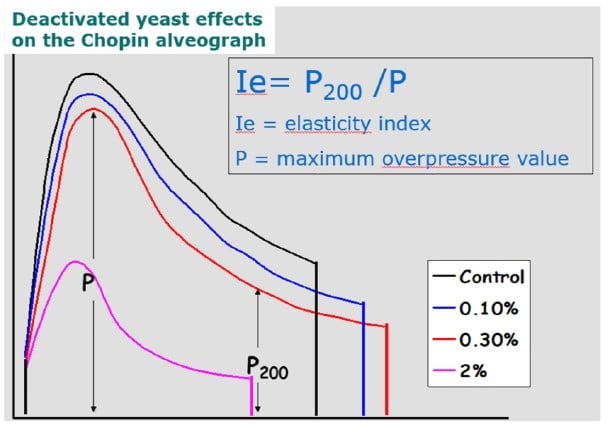

Many bakers regard deactivated yeast as their ‘secret ingredient’ for enhancing dough characteristics. It aids in reducing Shrinkage and elasticity, increasing dough extensibility and machinability, and elevating the visual appeal of baked goods, all of which reflect the artisanal expertise of the baker.

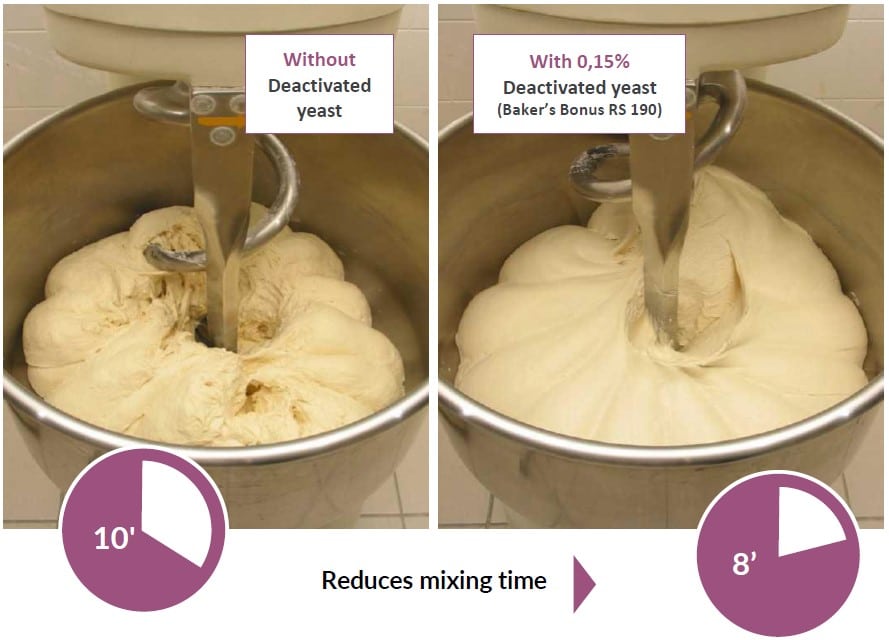

Incorporating deactivated yeast into your dough offers several key benefits, including a reduction in the overall mixing process up to 30% less time. This is achieved through the faster dough smoothing process.

Over the course of a production shift, this translates into the possibility of less required mixing times for each batch of dough, leading to continuous improvements and bakery energy savings. As a result, the advantages extend beyond just improved dough quality.

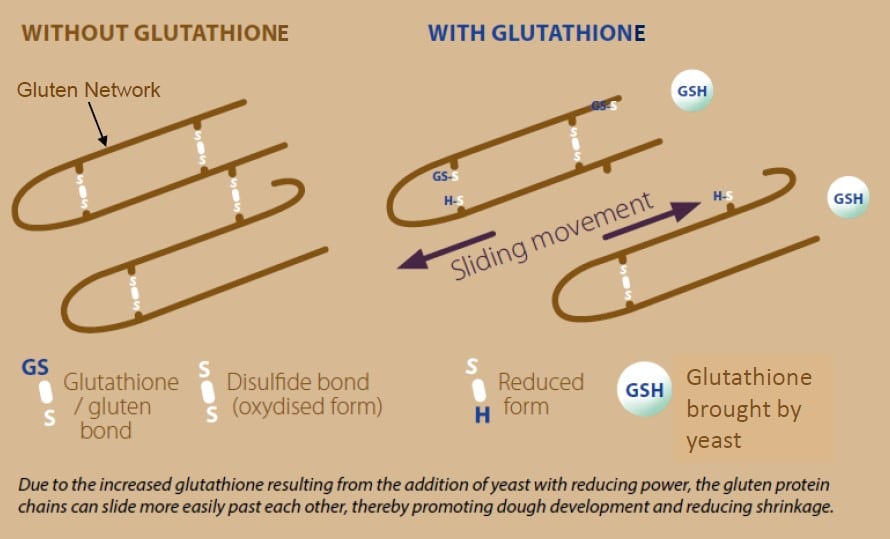

Yes, deactivated yeast is a natural reducing agent rich in glutathione, which is used to achieve a more voluminous end product with consistent quality. Additionally, deactivated yeast helps maintain the structure of extruded doughs.

However, when compared to L-cysteine, a reducing agent of either animal or bacterial origin, which operates on the same principle as deactivated yeast, there are some notable distinctions. Unlike yeast, L-cysteine is classified as a food additive (E920), which may raise concerns for those seeking cleaner label solutions. The use of L-cysteine is restricted in certain countries, adding regulatory complexity to its use. It’s also worth noting that using L-cysteine requires very precise dosing and specialized equipment due to its concentrated nature.

With all these benefits in mind, it’s worth emphasizing that the label declarations of RS 190 deactivated yeast clearly indicate that it is, in fact, yeast.

Deactivated yeast boasts numerous benefits that can enhance various aspects of dough preparation across a range of applications:

While this list showcases some of the key applications, it’s by no means exhaustive. To explore even more possibilities and discover how deactivated yeast can benefit your specific dough needs, please reach out to our expert team. We’re here to help you elevate your baking creations to new heights.

Deactivated yeast is derived from live yeast that has undergone a specific fermentation process and thermal treatment. This process inhibits its fermentation capabilities and breaks down its cell walls, making its glutathione content available and soluble in its environment. Deactivated yeast is a natural product, and as such, it is not classified as a food additive according to regulations. Its labelling may vary by country, often referred to as simply “yeast”.

During the mixing process, gluten strands interlace and reconfigure, forming a network that traps the CO2 gases generated during fermentation. Within this network, redox reactions create disulfide bonds in gluten proteins, which largely contribute to the dough’s viscoelastic properties.

Deactivated yeast, rich in glutathione, acts as a natural reducing agent. It is used to enhance dough volume and ensure uniform quality in the final product. Additionally, deactivated yeast helps maintain the structure of extruded doughs.

In addition to the end product specific advantages offered by RS 190, these benefits extend to significant improvements in all kinds of dough applications. Beyond the previously mentioned benefits, such as reduced mixing time (leading to lower dough temperature), deactivated yeast also enhances several key processes:

With such a wide array of benefits, it’s worth considering Baker’s Bonus RS 190 deactivated yeast for your production needs. Contact our baking experts to learn more about how you can enhance your baking processes with Baker’s Bonus RS 190 deactivated yeast today!

subscribe to our

newsletter

Get in touch with Baking with

Lesaffre’s news and updates