As bakeries work to meet growing production demands and tackle sustainability challenges, maintaining dough stability during production is more crucial than ever. Beyond just managing heat, bakers are looking for ways to streamline operations, cut costs, and reduce their environmental footprint.

At Lesaffre, we understand the critical importance of keeping operations efficient, sustainable, and adaptable to today’s demands. That’s why we developed T-Control™ 10.25 - an innovative solution designed to help industrial bakers maintain dough quality and reduce waste, even during unexpected production interruptions.

A Smarter Solution for Forward-Thinking Baking

In the world of baking, refrigeration and freezing have long been the go-to solutions for controlling fermentation and ensuring dough stability. However, these methods often involve significant investment in equipment, higher energy costs, and high CO₂emissions.

This unique system combines two components working in synergy:

- T-Control™ 10.25 Yeast – a specialised yeast designed to control fermentation and prevent dough from over-developing.

- T-Control™ 10.25 Improver – strengthens the gluten network and supports fermentation control to deliver stable, processable dough.

T-Control™ 10.25 offers a smarter alternative:

- Controlled fermentation at ambient temperatures

- A highly tolerant dough that maintains volume and structure for several hours from the time at which the dough is ready to bake without requiring cold storage.

- Reduced energy consumption and a lower carbon footprint.

Together, these elements ensure that dough remains workable and of high quality even during line downtime, giving bakers the flexibility to adjust production schedules and reduce waste.

Proven Performance in Real-World Trials

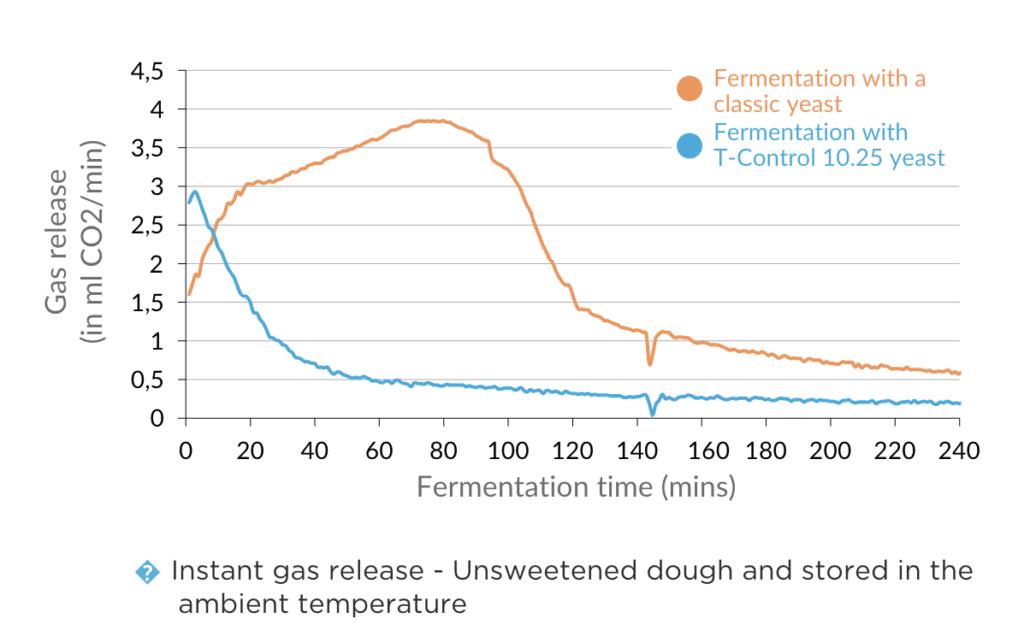

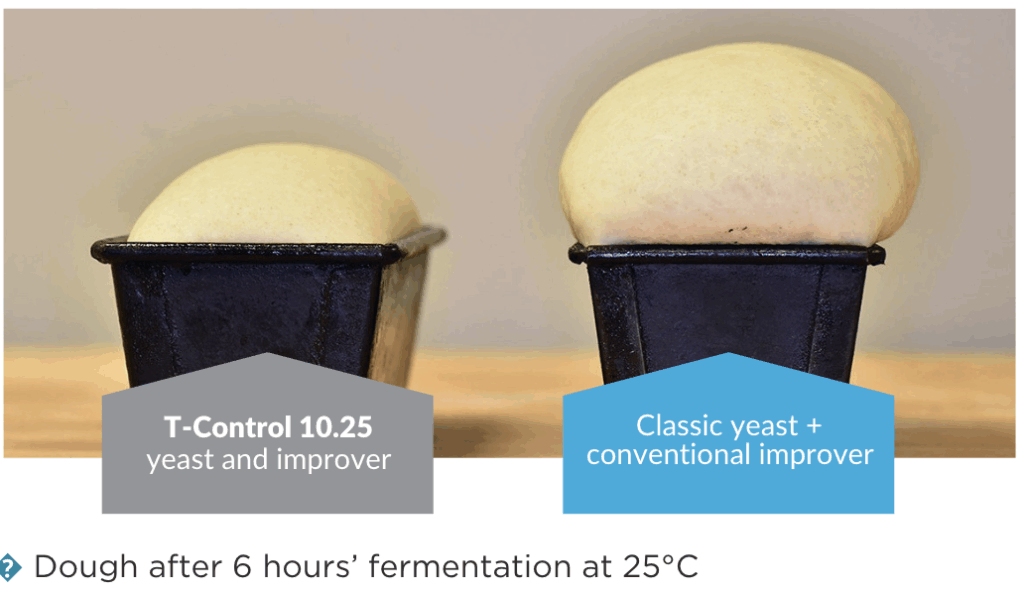

Trials using the Chorleywood Bread Process compared standard high-active yeast with the T-Control™ 10.25 system under extended fermentation conditions (up to three times longer than standard).

The results demonstrated:

- Maintained loaf volume – with no collapse or misshapen products.

- Consistent shape and crumb structure – even after extended proofing at ambient temperatures.

- Reduced waste – dough remained stable and processable, eliminating the need for costly rework or discard.

These benefits extend across a range of applications, including tin bread, pizza bases, speciality breads, and more – protecting baker’s from line stoppages disrupting product quality.

Why Choose T-Control™ 10.25?

Beyond its technical performance, T-Control™ 10.25 provides meaningful operational and environmental advantages:

Improved production management and flexibility.

Minimized waste and energy savings.

Consistent quality of freshly baked bread, all day long.

Resilience against unplanned line downtime.

Reduced reliance on refrigeration and freezing, lowering operational costs and environmental impact.

By helping bakeries to better control their processes, T-Control™ 10.25 contributes to more sustainable and efficient operations – a key priority in today’s baking industry.